The Impco model J regulator is the most popular LPG regulator on the market today, yet it is no longer used in current models of forklifts due to emissions regulations.

Impco model J regulators are found in a most brands of forklifts along with other LPG powered equipment like Tennant or American Lincoln scrubber units and even Zamboni ice resurfacers.

Replace or Rebuild?

Inside the model J are diaphragms made of hydrin or silicone. These wear out or tear and need to be replaced. The first decision you’ll have to make is if you want to replace the entire model J unit or rebuild the unit with a repair kit. Either decision is fine, it just depends on how you value your time.

You will see in the tutorial below that rebuilding a model J is pretty simple. There are times when a model J might be mounted inside a forklift where it’s easier to rebuild the unit instead replacing the entire unit. It just depends on the location of the model J.

How the Part Numbers are Designated

One more note. Model J is Impco’s designation for an entire series of LPG regulators. There’s a method to how the Impco part numbers work:

Model JB = Model J with Blue spring. Blue spring units have Neg. 0.37 kPa pressure. This is the standard and most common model J.

Model JO = Model J with Orange spring. Orange spring units have Neg. 0.12 kPa pressure. This is the lease common model J. You should stick with the model J that is already installed in your forklift.

After the letters JB or JO, you sometimes see a -2 like this: JB-2. The -2 indicates the diaphragms are manufactured from silicone. No letter means the diaphragms are made from black hydrin rubber. Silicone (yellow) diaphragm material is the optional upgrade material that provides excellent flexibility in cold weather climates and is more resistant to chemical contamination. They can be used interchangeably, if you want to upgrade, go with the silicone material.

Rebuilding the Model J

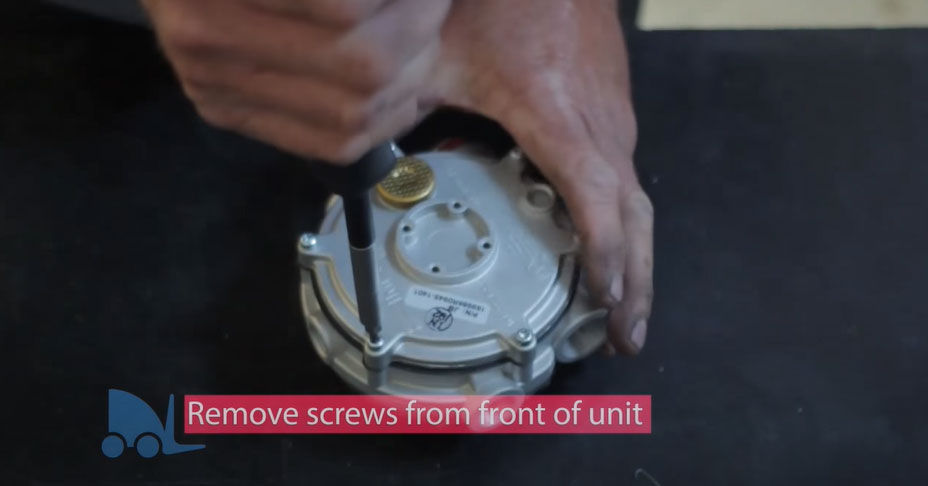

Remove screws from front of unit. The screws are typically 9-32 x 7/8″ Torx style

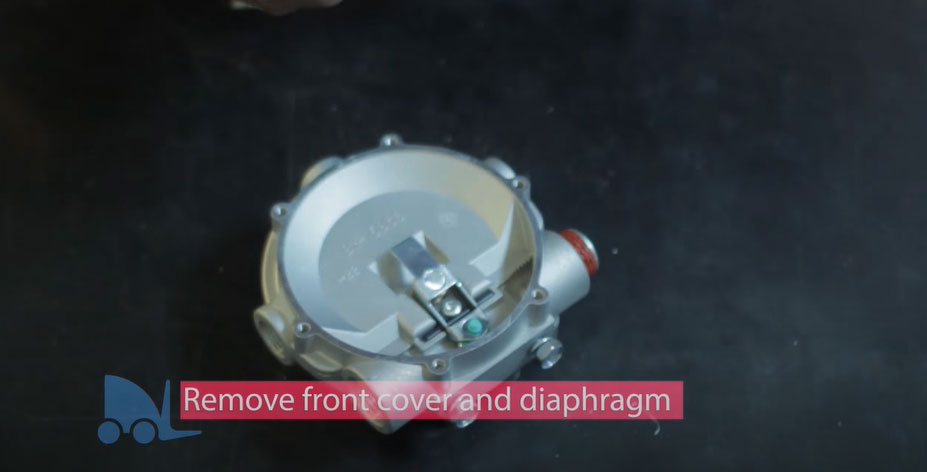

Remove diaphragm from inside cover

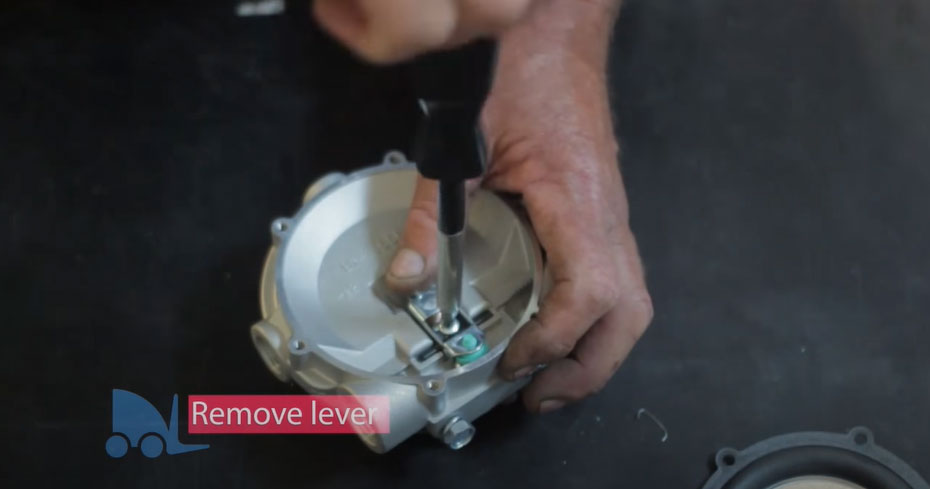

Remove lever. Screw is also a Torx screw

Remove the screws from the back of the model J unit.

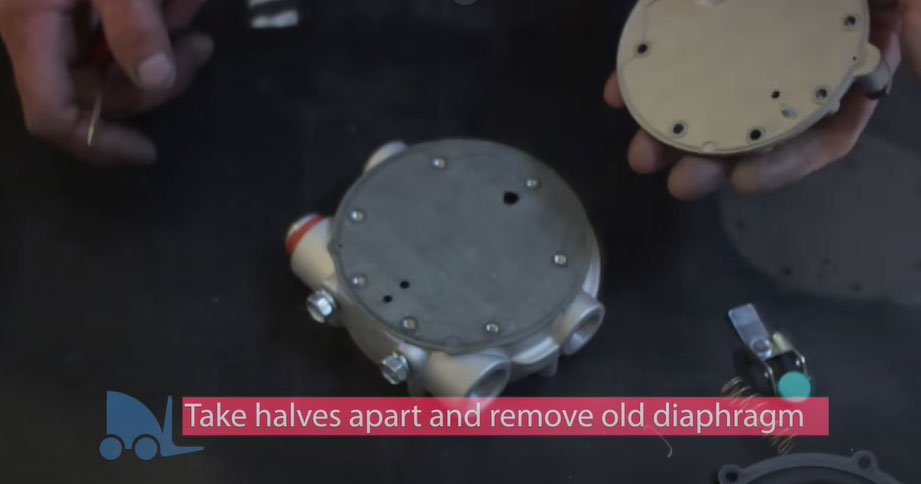

Take the halves apart and remove the old diaphragm.

Re-install the diaphragms and metal seat.

Re-install cover and screws

Re-install cover and screws

For full video: click here