| Product Name | IMPCO Model J Regulator |

| Aftermarket replacement for | HYSTER |

| Code/SKU | 068jb |

| Weight | 2.10 POUNDS |

| Warranty | 6 months |

Genuine IMPCO Model J Regulator

One of the most most widely used, trustable and easiest-to-operate regulators available.

Replacement for:

- HYSTER 0213549

- NISSAN 16310-90H71

- NISSAN 16310-90H72

- TOYOTA 23530-U2000-71

- TOYOTA 23530-U2001-71

- YALE 517079800

The Impco Model J regulator/vaporizer is known for its dependable performance and consistent pressure output. Its reliability, even when dealing with substandard fuel quality, has established it as an industry standard for many years.

There are two available vapor outlet pressures for the Impco Model J regulator. The standard Impco Model JB (this version) delivers -1.5 inches of water column (0.37 kPa), while the optional JO (J-Orange) offers 0.5 inches of water column (0.12 kPa). The port size and mounting pad positions are identical to those of the Impco Cobra regulator, providing compatibility and flexibility in installation. Additionally, this regulator includes a primary pressure test port and offers "left" or "right" fuel outlet options, allowing for versatile configurations in your setup.

You can get the Impco COBRA regulator here.

Checking IMPCO Systems for high CO Levels.

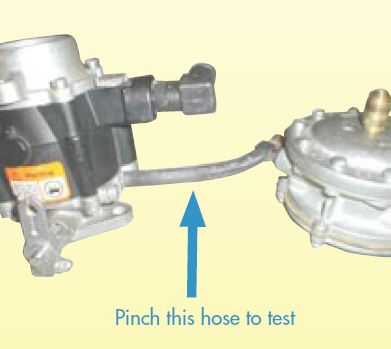

Step 1: Squeeze Hose

Impco VFF30 emissions

To test the vacuum hose on the VFF-30, use a needle-nose pliers to clamp it. If the engine RPM changes, it's an indication that the o-ring seal is faulty. If the engine continues running or the o-ring is confirmed to be bad after disconnecting the hose, you'll need to either replace or rebuild the Impco VFF-30. An alternative method for checking the system's integrity is by measuring carbon monoxide levels.

*Note: If your forklift is equipped with an electric lockoff, there's likely a vacuum safety or oil pressure switch connected to it. It's important to know that disconnecting these safety components is against regulation (refer to NFPA Pamphlet 58).

Step 2: Prime

Press the primer button while the engine is running on the Model J vaporizer-regulator. Note that IMPCO no longer manufactures a Model J with a primer button, but you can still find primer buttons on Impco model J generic units that we carry. When you press the button, the engine should either stall or shut down entirely, then return to idle once you release it. If it doesn't, or if pressing the button causes the engine to rev up, you'll need to adjust the air-fuel mixture in the mixer. For a step-by-step guide on rebuilding a Model J, check out the video linked here. You can also find a video tutorial on rebuilding the Impco VFF30 here.

Step 3: Air-Fuel Ratio Adjustments

Rotate the idle mixture screw (located on the mixer) counterclockwise to its limit. This should result in a decrease in carbon monoxide emissions.

Step 4: Air Filter

Remove the air filter and inspect its condition. If emissions either increase or decrease after removing the air filter, it's time to replace it with a new one.

Step 5: Mixer

If you haven't encountered any issues in steps 1-4 but carbon monoxide (CO) levels remain too high, it's likely that the mixer needs to be replaced. In most cases, you can swap your Impco Model 50 carburetor/mixer for a new Impco Model 100 or 125 with minimal modifications. If that's not an option for your setup, consider upgrading to a Model 55.

Step 6: Air Valve

To inspect the air valve in the Impco Model CA100/125 mixer, remove the four screws securing the mixer cover. Once opened, check the air valve, which should be part AV1-14-4; if it's different, replace it with the correct part. Examine the metering cone to ensure it's clean inside and doesn't show any signs of wear. If you notice any marks indicating that the valve is rubbing, you can gently sand the guide to smooth it out or replace the air valve entirely.

If the fuel mixture still seems off, you can try installing a lean air shim. Start by placing the first shim on the metering cone lip and then measure the emission levels. If there's only a slight improvement, add a second shim and re-check the emissions.

*To clean the air valve, use a solvent solution but avoid washing the diaphragm or using abrasive cleaners on any parts. Also, ensure the gas valve cone is securely fastened in the body housing to prevent leaks or malfunctions.

Step 7: Power Mixture Setting

Emissions should be within an acceptable range when the forklift is idling. To adjust the power mixture, load the mast by tilting it all the way back or forward. If the exhaust analyzer indicates a rich condition, adjust the power valve, also called the gate valve, by turning it to the "L" position to lean out the mixture.

Impco facts you might not have known

We have several variations of the Model J available:

Model JB - The B in Model JB signifies the blue spring, which is the most widely used version of the Model J regulator. This blue spring provides a negative pressure of 0.37 kPa (1.5 inches of water column). The Impco Model JB's diaphragm is crafted from hydrin, making it suitable for a wide range of applications

Model JB-2 - It is similar to the JB; the only difference is that its diaphragm is made of silicone, which makes it suitable for cold climates.

We offer a generic model JB that includes a primer button. Some older forklift models still require a primer button on the LP regulator, and we're among the few online sources offering this version.

REBUILDING MODEL J REGULATORS:

Model J regulators can be repaired and rebuilt with repair kits made of either hydrin or silicone. There is no limit to the number of times you can rebuild a Model J regulator.

COBRA

Impco designed the successor to the Model J regulator and initially named it the Model K, but quickly changed the name to COBRA after learning that the U.S. Trademark Office would not trademark a single alphabetic letter. The COBRA regulator is fully compatible with applications designed for the Model J, but it’s important to note that a Model J should not be used as a replacement in a COBRA-specific setup.

We also offer COBRA repair kits, and yes, you can rebuild COBRA units as many times as needed.

The Model J, when used with the VFF30 lock-off, is a solid choice if you're looking to convert your system to LPG or to replace an outdated or discontinued propane system.

COMMON QUESTION: If my forklift came with a Model JO, can I replace it with a Model JB or JB-2?

A: Yes, you can, as long as you understand the difference between hydrin and silicone diaphragms, and ensure they meet your needs.

The impco model j regulator, performs as well or exceeds the performance of OEM Forklift Propane Parts while keeping affordable pricing.

Intella offers fast and reliable shipping across the US and Canada with next day delivery available when needed. Click on the shipping tool above to calculate the delivery cost of your impco model j regulator. Feel free to contact us at 616-796-6638.

With an extensive catalog of aftermarket Forklift Propane Parts we are sure to have the right aftermarket part for your needs.

Estimate Shipping

Check If There's an Intella Mechanic in My Area

Enter a zip code below. If a Mechanic is found you will see their price and your option to accept the service.

Example: 29325

Other items you might be interested in...

Customers Who Bought This Item Also Bought

We want to make sure you order and receive the right part to fix your forklift. Please review the return policy before and click the box on the prior screen before ordering. If you have any questions at all, please call us 616-796-6638; we can help ensure you order the correct electronic part for your forklift.

To start a return we will need your email, order number, part number and reason for return. Please email us with this information to begin the return process.

If you click on the box you recognize:

- All electrical parts/components are subject to internal damage that may be apparent or tested for. Such damage can be the result of improper handling/installation or subjecting the part to adverse environmental conditions (heat, static electricity). For this reason, all electrical parts/components are NON RETURNABLE.

- On items that are eligible for return, return authorization is mandatory before returning product to our warehouse.

- Returns must be made within (30) days of you receiving an order and by prior approval. Parts must be returned within 7 days of receiving authorization to return a part.

- If your order is damaged in the process of being delivered by any carrier (UPS, USPS, FedEx or Trucking Co, etc), they are responsible. Examine all goods upon receipt for possible shipping damage and report any such damage to the carrier immediately. Keep all the packaging from the damaged shipment as the carrier may need to examine it in the claims process.

- Restocking fee is 25%.

- Package items to protect the original factory packaging so that they arrive here in perfect condition to be put back in inventory as new merchandise.

- Refunds for shipping charges will only be if we shipped the wrong merchandise.

- Special order items that we do not stock are not returnable.

- Paint is non returnable

- Gasket sets are also non returnable once they have been opened.

- All electrical parts/components are subject to internal damage that may be apparent or tested for. Such damage can be the result of improper handling/installation or subjecting the part to adverse environmental conditions (heat, static electricity). For this reason, all electrical parts/components are NON RETURNABLE.

- Once any item has been installed or used it is not returnable for a refund, and can only be exchanged under our warranty policy

More Policies

See all of our policies on our Policy Page