“How much weight can my forklift lift?” It’s a common question for many and the answer starts by looking at the forklift data tag on your forklift.

Q: What is a forklift data tag?

A: A forklift data tag, also called a nameplate, load plate, or data plate, concisely displays information about the lift truck for the use of its operator. According to OSHA, all operators must be trained in reading a data tag and understanding what it means so as to maintain a safe work environment for all employees near or in contact with the truck. A truck cannot legally be operated without a readable data tag.

Q: What does a forklift data tag look like?

A: By OSHA regulation, the tag must be durable, corrosion-resistant, and legible. It is often displayed near the driver’s seat for easy accessibility, and it typically includes some sort of warning about proper use of the lift truck. Be sure to read this warning.

Q: How do I read a forklift data tag?

A: The information on a data tag can look daunting, but with familiarity, reading it can be quite straightforward.

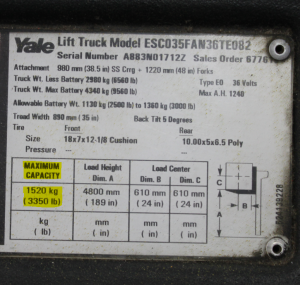

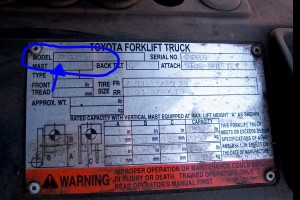

• Model, type, and serial number are often displayed near the top of the data tag.

• Mast information is sometimes displayed on the tag as well. In the example above, it is shown in the bottom half of the tag with the use of a diagram. Other tags may include this information without a diagram in the upper half of the tag. Mast information includes maximum height, number of stages, and sometimes maximum degree of tilt.

• Truck weight is often displayed in the upper half of the tag.

• Capacity and load center are typically shown in a table-like format. They are in table format to include room for the capacity and load center when certain attachments are used.

• Somewhere on the tag, designation of compliance with safety standard requirements must be present, which is the responsibility of the manufacturer. Often the data tag itself has a type of serial number as well, so that it can be tracked if need be.

• Information on wheels, tires, and batteries may also be included, but this is not necessary by OSHA standards.

Q: When do I need a new forklift data tag?

A: If you add a new attachment that changes the configuration of the forklift, you need to order a new data tag from the manufacturer. Some manufacturers provide these at no charge, others charge up to $150 per tag. When ordering the data tag, the manufacturer will want to know any attachments that have been installed on the forklift after the forklift was shipped from the factory. Attachments such as side shifters, clamps, rotators, fork positioners, etc change the capacity of the forklift.

Q: How do I determine lift capacity from a forklift model number?

A: There are some simple ways of knowing the lift capacity of a forklift without looking at the data tag. While the data tag is the most reliable method of checking capacity, the model usually designates the standard lifting capacity of the forklift without any attachments.

American manufacturers such as Hyster, Yale, Crown, and Raymond will typically have a number designation in their model which, if multiplied by 100 will equate to the rough lifting capacity of the forklift. For example, a Hyster S50FT will have a lifting capacity of 5,000 pounds before any attachments are installed. A Yale GLC120 will have an estimated lifting capacity of 12,000 pounds before any attachments.

Japanese manufacturers such as Toyota, Nissan, Komatsu, Mitsubishi, TCM, NYK will designate the lifting capacity in metric form. A Toyota 7FGCU25 will have a lifting capacity of 2,500 kilograms or 2500 x 2.2 pounds per kilogram = 5,500 pounds. A TCM FCG15 will have a lifting capacity of 1,500 kilograms (x 2.2 for pounds).

These are only general guidelines and useful for determining approximate lifting capacity from the model number before any attachments are added. If you want to know the exact lifting capacity of any forklift, check out the data tag!

For more information, see www.osha.gov/SLTC/etools/pit/forklift/basicparts/nameplate.html.