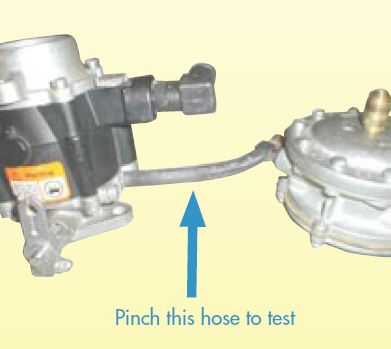

Step 1: Squeeze Hose

Use a needle-nose pliers to pinch the vacuum hose on the VFF-30. If the RPM speed changes, the o-ring seal is bad. If after disconnecting the the engine doesn’t die or the o-ring is bad, the needs to be replaced or rebuilt. You can also test this using carbon monoxide readings.

*If you have an electric lockoff in your lift truck, you will also have a vacuum safety or an oil pressure switch. It is against regulations for these to be disconnected (see NFPA Pamphlet 58).

Step 2: Prime

Push the while the engine is running on the vaporizer-regulator. IMPCO no longer manufacturers a model J with a primer button. However, primer buttons are available on Impco units which we offer. The engine should stall or completely shut off while pushing the button and start back up to idle as soon as you release. If this doesn’t happen or pushing the button causes the engine to speed up, adjustments are needed with the air-fuel mixture in the mixer. To watch how a Impco model J is rebuilt, check out this video . A video on how to rebuild an Impco VFF30 can be found here.

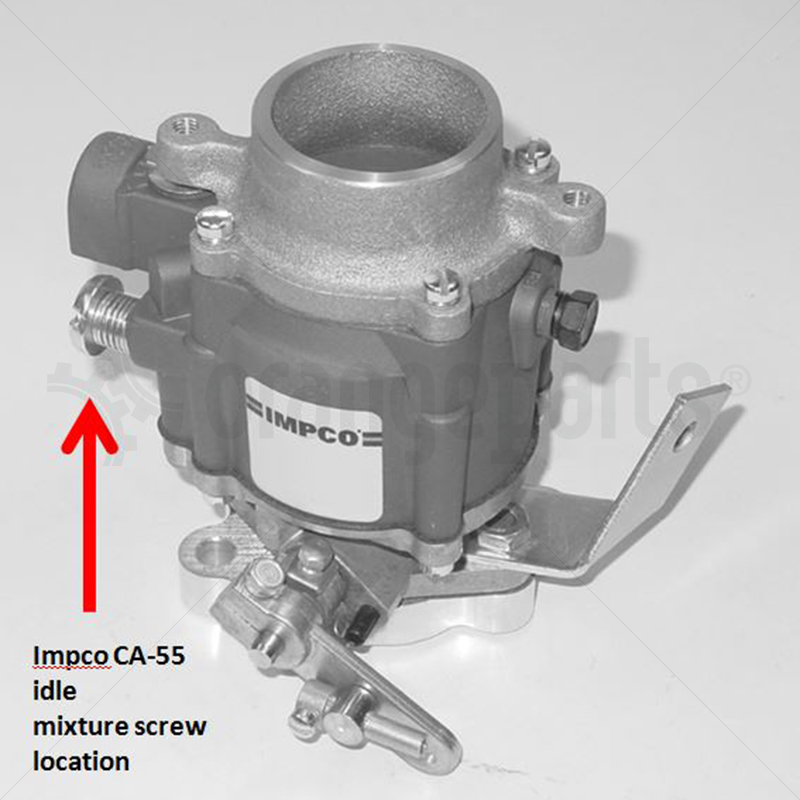

Step 3: Air-Fuel Ratio Adjustments

Step 3: Air-Fuel Ratio Adjustments

Turn the idle mixture screw (on the mixer) counterclockwise as far as possible. The emissions reading should decrease in carbon monoxide.

Take out the and inspect it. Replace the filter if there is an increase or decrease in emissions after the air filter is removed.

Step 5: Mixer

If you haven’t had any problems with anything in steps 1-4 and CO levels are still too high, the mixer must be replaced. Usually, you can replace your Impco Model 50 carburetor/mixer with a new Impco Model 100 or 125 with minimal adaptations. If this is not the case for you, go with a

Step 6: Air Valve

There are 4 screws holding the Impco Model CA100/125 mixer cover that need to be removed in order to check out the air valve. (It should be part ; if not, replace with the correct part.) Make sure the metering cone is clean on the inside and there are no signs of wear. If you see marks implying the valve is rubbing, either sand the guide gently or replace the air valve. A lean air shim or 2 may be installed at this point if the fuel mixture still isn’t right. Install the first shim on the metering cone lip and check the emission levels; if only a minor improvement, add the second shim.

*Clean the air valve with a solvent solution. Do not wash the diaphragm or use an abrasive cleaner on any parts. Make sure the gas valve cone is tight in the body housing.

Step 7: Power Mixture Setting

Emissions should be at an acceptable level when the truck is idling. Set the power mixture and load the mast by tilting completely back or forward. If you have a rich condition based on the exhaust analyzer, turn the power valve, or gate valve as its also known, to the “L” position.